Imagine having a digital clone of your business’s physical space, machinery, or any other asset. This is what a digital twin is. It can help you keep track of performance, improve processes, and predict outcomes.

To avoid investing in something that may not work, you can create a digital business solution to test it out. However, it’s crucial to know how it works and its structure to use it effectively.

In this blog, we’ll discuss the digital twin’s architecture and steps on how to develop one.

Digital Twin Types by Application

To use a digital twin model in the best possible way, you need to learn about the existing types. This will help you build an optimal digital twin simulation for your business needs.

As such, virtual twins differ in application and hierarchy. There are four categories of digital twins arranged in a hierarchy. The DTs may represent parts, systems, products, and processes.

We have already covered these categories in our custom digital twin development guide. Check it, if you want to get a solid understanding of this technology from the ground up.

For those familiar with digital twins, here’s a breakdown of digital twin categories by application. This will help you define your digital twin software requirements before the development process.

Autonomy Twin

Autonomy twins are capable of performing complex tasks such as image and object recognition. They are fully independent and can learn and act on behalf of users. Such twins have robust decentralized computing capabilities.

Manufacturing uses enterprise digital twins for several purposes. Namely, predicting process optimization outcomes, improving workflows, identifying system faults, and automating operations.

Simulation Twin

Digital twin simulations use AI to predict the future operational states of the system. They are commonly used for predictive maintenance.

For instance, a DT simulation of a residential building. It may help you predict which parts of it will age faster than others and need repairs. This may help the building owners to avoid accidents and schedule repairs.

Operational Twin

You can use this digital twin construction for providing big data for decision-makers. This DT includes control capabilities. The model is interactive, so the users may change its parameters. It allows them to see how a system will operate in different conditions.

For instance, a power plant system may adjust the amount of electricity produced to the current demand. Operational twins are also used in industrial manufacturing and are an essential part of smart city technology.

Status Twin

Enterprises use such twins for basic status monitoring (alert systems, dashboards, etc). Their aim is to monitor, capture, categorize, and showcase operation parameters. Status digital twins normally include visualization tools.

The use cases also include smart agriculture. DTs facilitate the process of monitoring the condition of soil and plants, air humidity, and the state of an environment.

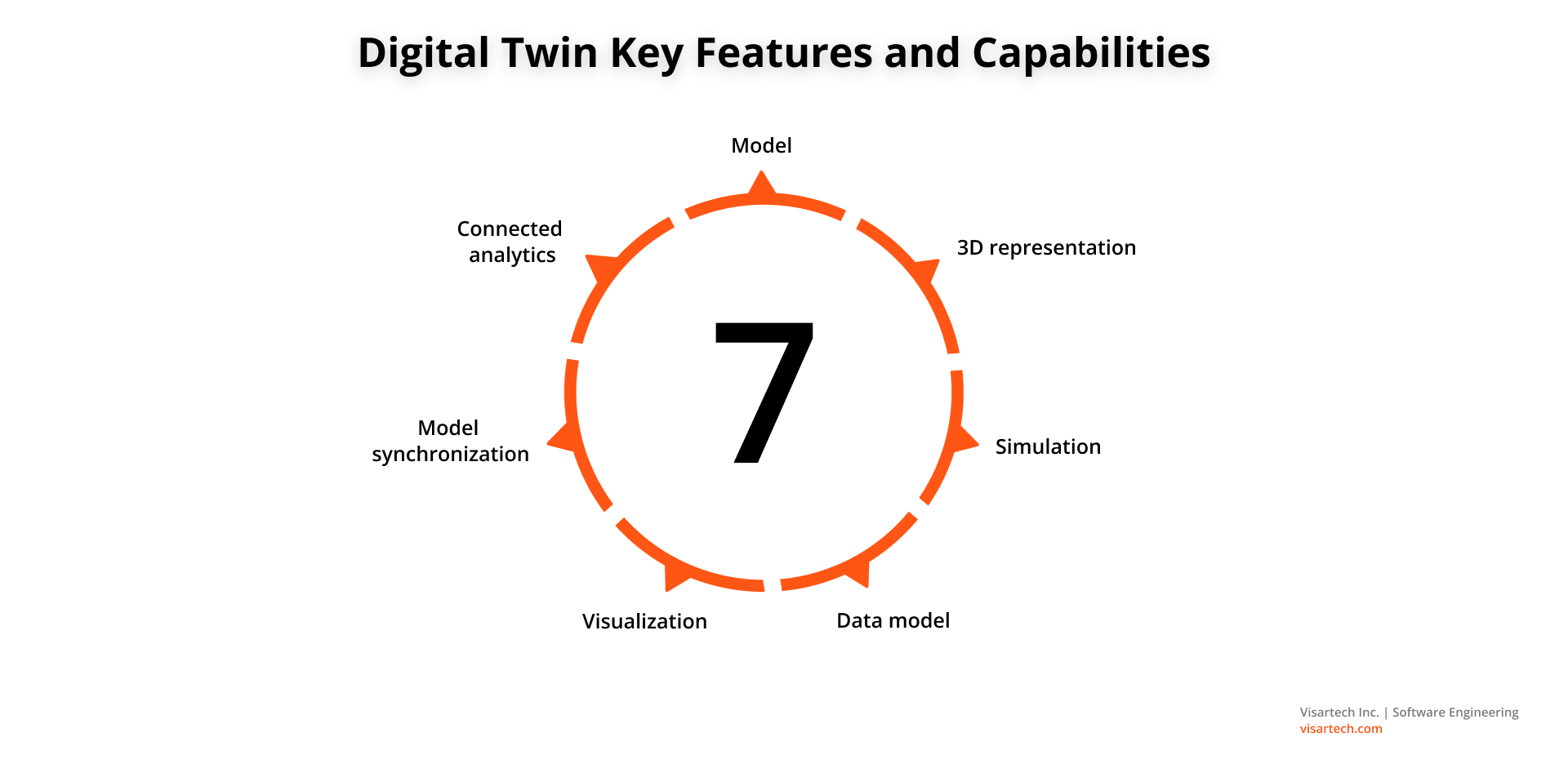

Key Features and Capabilities of a Digital Twin

Before creating a digital twin, it’s important to know its main features and capabilities. Let’s consider them in more detail.

- Model

A digital copy of a physical device precisely replicates its properties and characteristics. Digital twins allow users to create 3D models of physical objects in a built environment and track their behavior.

- 3D representation

A 3D representation is an exact visual copy of a physical device. It creates a nearly real-life experience, helping you quickly understand the data in analytic reports.

Read more: What Is Metaverse and How Businesses Can Benefit From It

Find out metaverse capacities and embrace virtual world solutions

- Simulation

The simulation software of a digital twin puts a virtual model of a physical device into a virtual environment. It also changes the environment’s parameters to track the device’s behavior in different conditions.

- Data model

A digital twin is capable of bringing users a real-time data model. It visualizes the connections between the elements of a physical device or system. It permits you to label data and delivers a transparent view of operations and processes.

- Visualization

This feature lets users view models on a standalone workstation or a mobile device. It gives instant insight into details related to the functionality of a device or system.

- Model synchronization

This outstanding feature aligns the digital model with real-world parameters. Modern modeling software is capable of doing it in real time. You instantly view the representation of all the physical updates in a digital twin construction.

- Connected analytics

Analytics gives you data based on the measured properties of a physical device. A digital twin platform uses ML algorithms and computations. Thus bringing insights into your device’s or system’s operations and behavior.

The exact features of a digital twin architecture will depend on your business needs and goals. But, here are some key components of a digital twin solution to give you an idea of how it works.

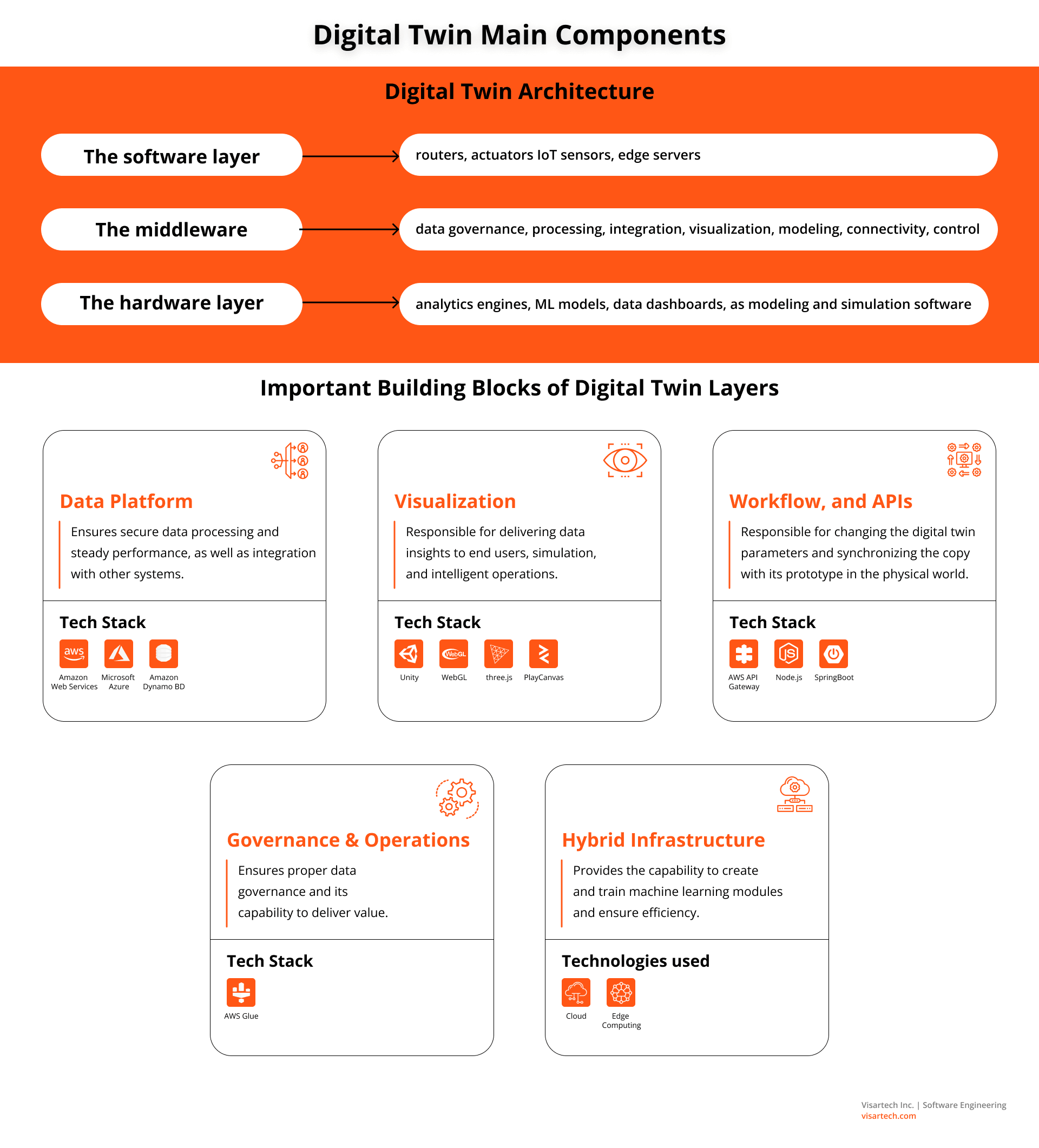

What Are The Main Digital Twin Components?

The digital twin architecture is, essentially, both physical and digital. It includes three layers:

The hardware layer comprises the physical components of a digital twin. These are routers, actuators IoT sensors, and edge servers.

The middleware is the data processing layer. It includes data governance, integration, visualization, modeling, connectivity, and control.

The software layer provides analytics engines, ML models, and data dashboards.

The most important building blocks of digital twin layers deserve a detailed description.

Data Platform

The Data Platform is one of the main digital twin components since it ensures secure data processing. Thus eliminating data lakes. The platform analyzes the data using machine learning and artificial intelligence. Then integrates it with other systems.

To do all of this, the Data Platform needs to store a lot of data. That’s why it uses cloud services to perform analysis.

Tech Stack: AWS, Microsoft Azure, Amazon Dynamo BD.

Visualization

A vital component of a digital twin platform. This model translates the status data, analytics insights, and forecasts into formats suitable for human perception. As a result, we get a connected environment of the virtual copy with the physical world.

The Visualization module handles delivering data insights to end users. The dashboards and commands of a digital twin rely on this module for correct functionality.

Tech Stack: Unity, WebGL, three.js, PlayCanvas.

Read more: Interactive 2D/3D Graphics for Web Projects

Discover WebGL capabilities your business can benefit from

Workflow, and APIs

Workflow and APIs serve to pull and share data from different sources for building a DT solution. It synchronizes the copy with its prototype in the physical world.

This module is all about workflows, operations, processes, and event-based flows.

Tech Stack: AWS API Gateway, Node JS/ SpringBoot.

Governance & Operations

Important elements of the data platform architecture. The digital twin is, essentially, a data powerhouse. So the Governance & Operations module is necessary to ensure that data is structured and available on demand.

This module ensures proper data governance and its capability to deliver value.

Tech Stack: AWS Glue.

Hybrid

The digital twin infrastructure is complex and combines cloud and on-premise elements. Hybrid infrastructure is necessary to support continuous integration and delivery. Furthermore, it provides the capability to create and train machine learning modules.

Technologies used: cloud and edge computing.

The digital twin architecture is a complex combination of physical and digital components. They work together to synchronize the digital twin with its physical prototype and provide data insights to end-users. With the right technology stack, a well-designed digital twin can provide accurate and timely insights.

How to Build a Digital Twin?

Virtual representations use advanced technologies. Thanks to this, they help businesses optimize operations, reduce costs, and enhance product performance.

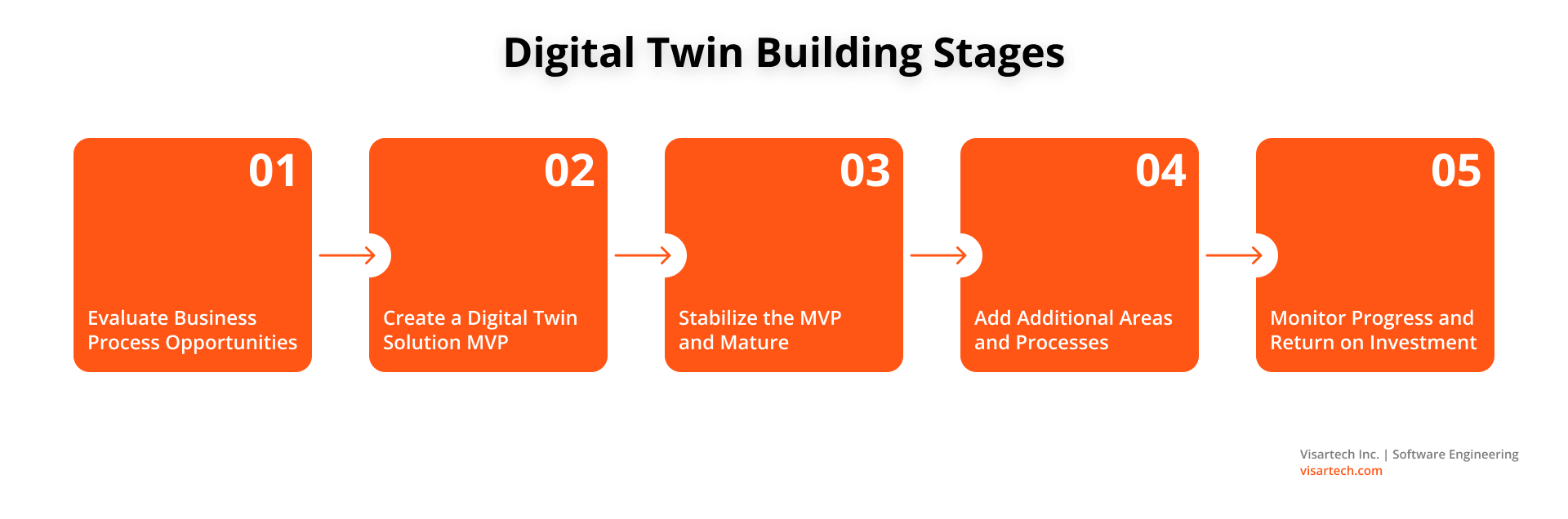

But, creating a digital twin is hard and takes a lot of time. In this part of the article, we’ll talk about the stages of digital twin building. From assessing process opportunities to monitoring progress and return on investment.

#1. Assess Process Opportunities for Your Business

At this stage, you should define the scope and scale of your DT solution. The list of questions to ask yourself at this point includes:

- Will you be replicating an entire system or device or just part of it?

- Who will be running the digital twin: your employees or end users?

- Will users be accessing it remotely or on-site?

- Which functions do you want to replicate?

At the end of this stage, you should define the digital twin platform functionality and the goals you want to achieve. Finally, when you have the feature set and specification, move on to the digital twin product development.

#2. Create an MVP Digital Twin Solution

The set of features from the previous stage will dictate your project’s tech stack and architecture. Before you build a minimal viable product (MVP), decide which features are absolute must-haves. After that think of others to add at later stages.

#3. Stabilize the MVP and Mature

Building an MVP version of your digital twin solution will help you test your product and implement changes. Thus you know what features or processes you need to add or exclude from your final product version. Allow your MVP to stabilize and mature before you proceed with the digital twin building.

#4. Add Additional Areas and Processes

When it comes to making changes and improvements, nothing works better than a real-life test drive. The MVP stage helps adjust digital twin requirements and decide which processes to replicate in the final version.

#5. Monitor Progress and Return on Investment

Once your digital twin platform is up and running, you’re not done yet. Digital twins are dynamic replicas of real-world assets. They change and develop in line with the current business needs. Tracking your progress and ROI makes sure the digital product delivers value.

By following these steps, you can ensure a successful digital twin implementation that delivers tangible value to your business.

Case Study: Digital Twin Transforming Business Processes

We recently helped an automotive company by creating a cool VR-based business process simulation platform. Our dedicated team used the Oculus Rift platform and Unity technology to make interactive XR features.

The business process solution we built reduced cycle time by 4 times and decreased lead time and costs by 5 times. It’s pretty impressive how digital twin technology can optimize processes and operations.

To see more examples of our digital twin case studies, you can visit the cases page.

Conclusions

Digital twins can be compared to a clear mirror that reflects a business’s real-world operations. This mirror not only shows the current state of affairs but also enables businesses to predict and plan for the future with accuracy and ease.

By simulating and optimizing processes, digital twins help businesses identify inefficiencies, streamline operations, and make informed decisions based on data. Just like a mirror that helps us present our best selves to the world, digital twins assist businesses in showcasing their most efficient operations.