The “create and then optimize” scenario no longer works for businesses of all domains. It requires additional costs to correct imperfections, slows down workflows, and leads to delays in production.

The custom digital twin development is here to change this situation. It rapidly and precisely analyzes and optimizes processes prior to physically creating a product or making a business decision.

Through this article, we will explain the concept and types of digital twins and what components are essential to develop this solution. You will also explore the differences between a 3D virtual twin and its similar counterpart, the advantages of creating the custom digital model, and associated costs.

What Is a Digital Twin?

The transformation of global business has led to the emergence and growth of a new era called Industry 4.0. It prioritizes advanced analytics, automation, and progressive technologies to achieve the best results possible. These changes are driven by solutions including cloud & edge computing, IoT, artificial intelligence, and digital twin development.

The last one is used in the Industry 4.0 to show the connection between the real and virtual worlds. Through this integration, you can create solutions for designing, engineering operations, and production concerns.

At its core, a digital twin is a virtual representation of a planned or actual physical product, system, or process that acts as its identical digital counterpart. It allows companies to control equipment and systems remotely, analyze datasets, and predict potential breakdowns or issues.

What sets it apart from similar concepts? The digital twin uses a two-way data link. Simply put, actions transmitted through a virtual model begin to perform in its physical counterpart.

That’s why digital twin development services are popular among industrial businesses. 96% of executives agree merging of digital and physical realms in the coming decade will revolutionize their respective industry.

“With a great variety of digital twin opportunities emerging right now, brands level up in both service or product delivery and internal business processes. And a well-designed digital twin becomes a lucky ticket to dynamic and efficient business performance.” Slava Podmurnyi, Forbes member

By demonstrating all aspects of business operations in a convenient and precise way, custom digital twin engineering replaces traditional approaches to decision-making. With that in mind, let’s see what elements are essential to create an effective virtual representation.

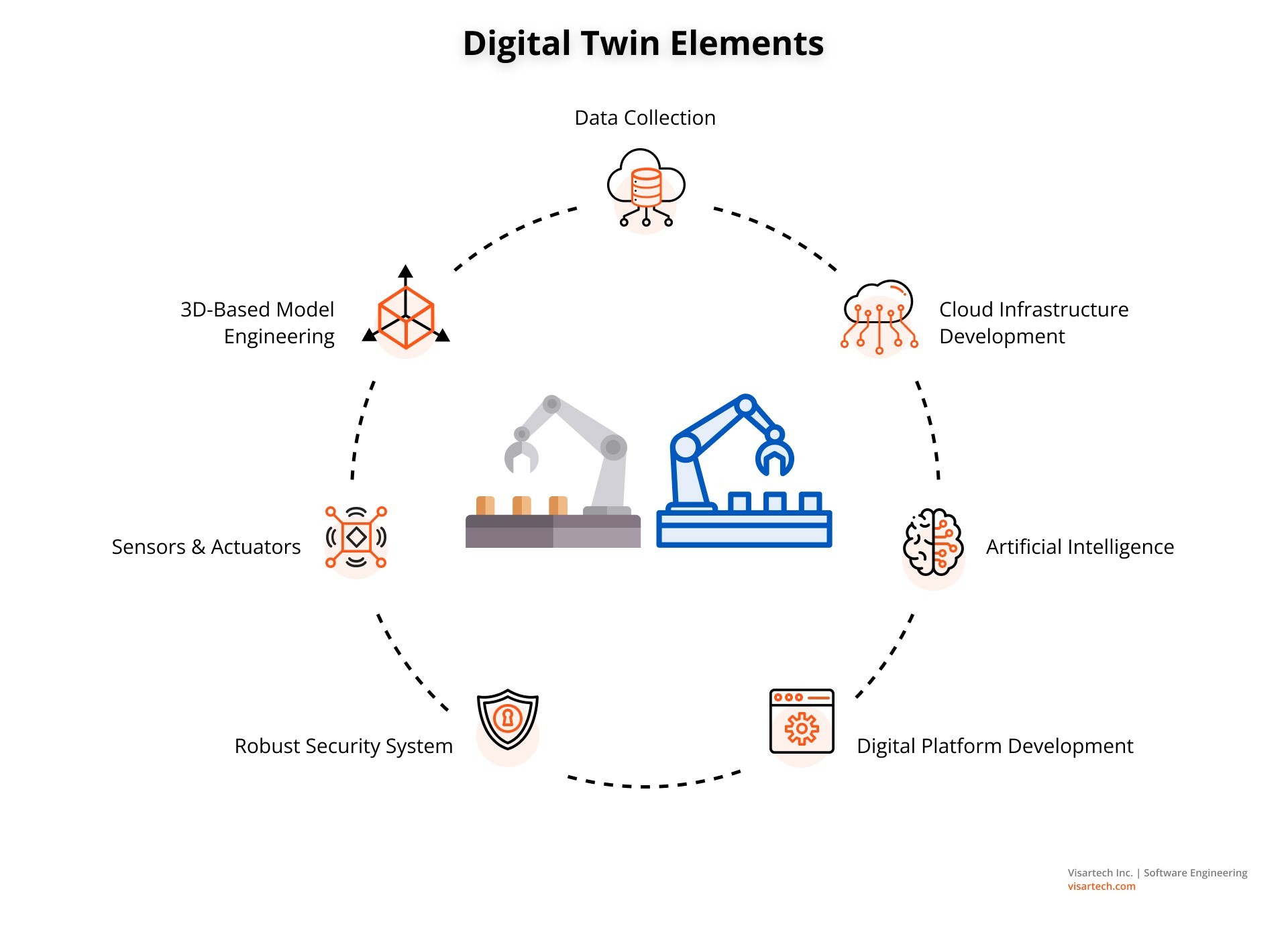

The Complete Overview of Digital Twin Elements

Although the digital twin development project involves the creation of unique virtual representations, all of them have the same basic elements. Some 3D twin components are responsible for collecting object data, while others analyze and predict its behavior or display the received information in a user-friendly way. Since digital twin implementation is impossible without these elements, it makes sense to review them in detail.

- 3D-Based Model Engineering

It’s developed using data collected from a real object and presents all the details of the item’s characteristics. Prior to implementing solutions in the real world, businesses use 3D software engineering services to better understand an object or process, forecast its behavior, and identify issues.

Read more: Interactive 2D/3D Graphics for Web Projects

Discover WebGL capabilities your business can benefit from

- Cloud Infrastructure Development

This part of the 3D model gives the space to store data gathered from sensors. Digital twin development companies use cloud infrastructure to provide access to information from anywhere, allowing users to interact with a virtual model via the Internet.

- Artificial Intelligence

AI helps to analyze, interpret and understand the data provided by the virtual model. This element is beneficial in decision-making, event forecasting, trend detection, and anomaly identification in real time.

- Digital Platform Development

This is a digital space where engineers observe, analyze and interact with a digital twin simulation. It could be cloud platforms, web & mobile applications, visualization tools, and specialized management systems.

Read more: What Is Metaverse and How Businesses Can Benefit From It

Find out metaverse capacities and embrace virtual world solutions

- Robust Security System

Since digital representations contain business data, it’s threatened by cyber attacks. That’s why enterprises should take cybersecurity measures and protect the 3D model from unauthorized access, data loss, or damage to its integrity. Your cybersecurity strategy may involve various activities such as following privacy regulations, using encryption for data in transit, and managing fault prevention and elimination.

- Sensors & Actuators

Sensors collect physical data of an object or system from the real world and convert it into a digital representation that software can read and understand. For example, information about temperature, humidity, motion, location, or vibration.

When you correctly develop and implement the digital twin elements mentioned above, you can get many opportunities for better optimization and decision-making. This also impacts the choice of scenario in which a virtual twin will work within your organization.

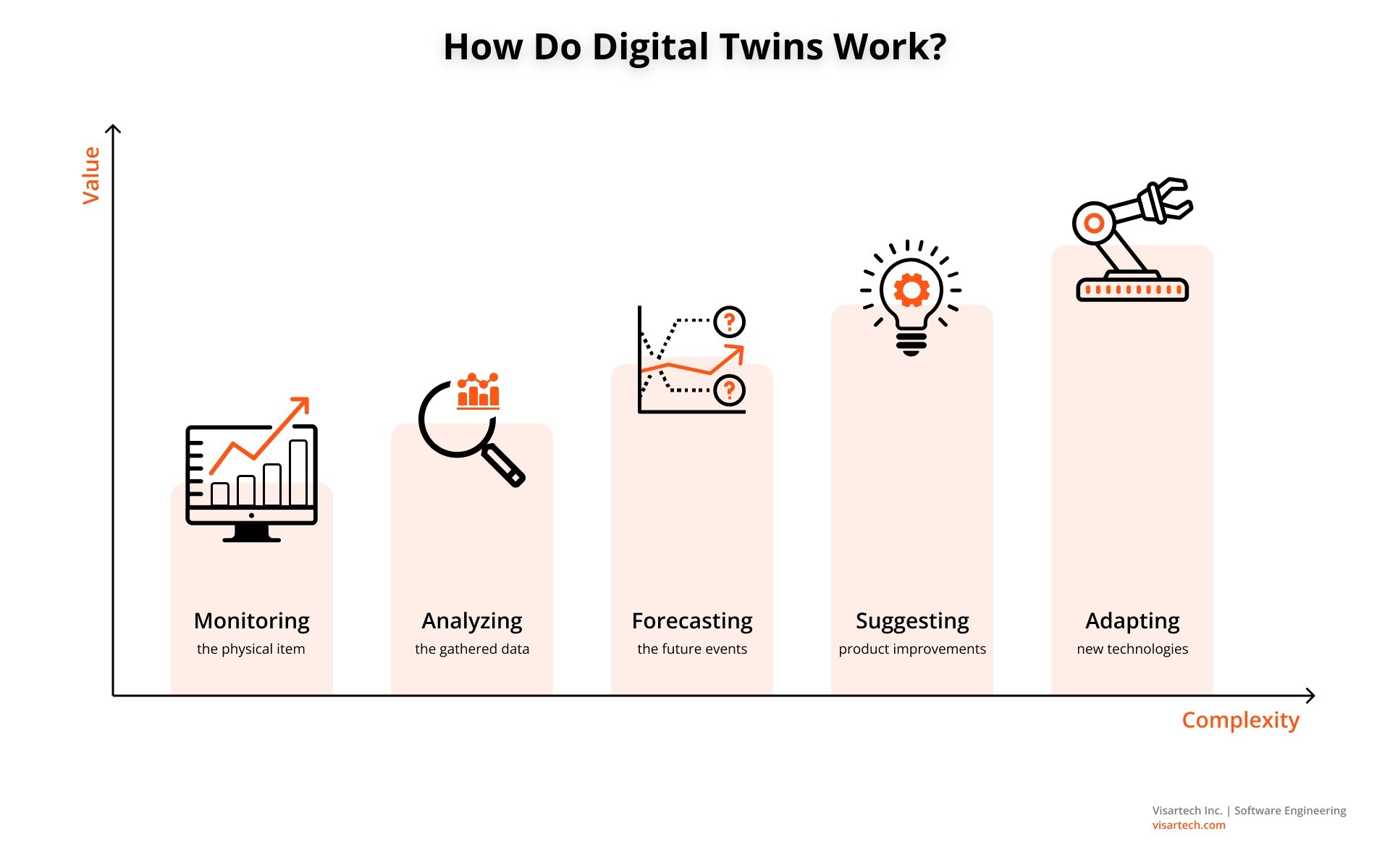

How Do Digital Twins Work?

To put it simply, the digital twin processes and interprets data from sensors, which allows it to track an object in real-time, predict its behavior and perform multiple test simulations. However, it’s important to understand that a virtual copy isn’t one algorithm. Instead, it works in five different scenarios:

Monitoring

The digital twin continuously keeps an eye on the physical object while gathering data from various sensors. Namely, it tracks physical characteristics, performance indicators, and environmental factors. Since all this data is updated in real-time, companies know what is happening with an item right now.

Analyzing

By leveraging built-in machine learning and analytical algorithms, digital twins represent valuable information and concealed patterns. For instance, if a digital twin simulation tracks a real object, it might spot specific traits or connections between those traits and the functionality of the unit.

Forecasting

Once the digital twinning has finished data collecting and processing, it uses the information to predict future events within the business. For example, digital twins can determine the company resources required for manufacturing a new product and access its market demand.

Suggesting

One of the custom digital twin development tasks is to model what-if scenarios. In practice, this means that you get suggestions from your digital twin data model about various components of the future product or its manufacturing chain. This allows companies to find the optimal operating parameters to achieve the desired results. Businesses also employ this strategy to improve their existing products or services.

Adapting

In the era of Industry 4.0, adaptability is a company’s ability to incorporate new technologies for operational optimization. Digital twin development services enhance this by accurately representing the organization’s current state and predicting potential issues, enabling quick adaptation and informed decision-making using new data.

The digital twin is a complex fusion of algorithms, technologies, and data-driven processes. Yet this complexity allows for real-time tracking, predictive analysis, and virtual representation of complex things which lead to enhanced efficiency and improved outcomes.

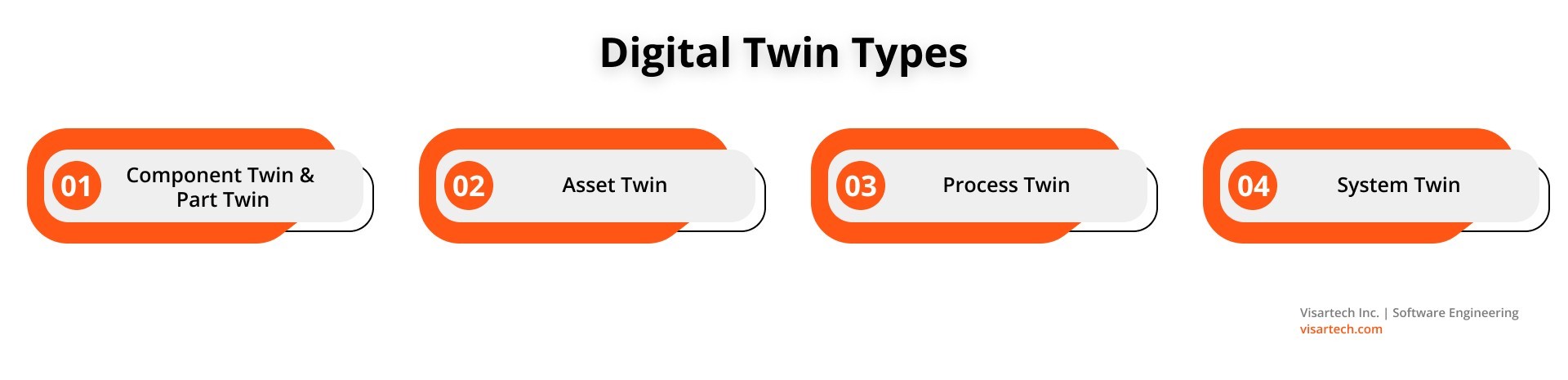

Main Types of Digital Twin

The hierarchy identifies four types of digital twins. Each of them has specific characteristics and purposes. The following analysis and examples of all virtual twin types will assist you in making the best decision for your company’s operations.

#1. Component Twin & Part Twin

A component twin is a virtual version of one element or part of a larger system. Its primary responsibility is to track and examine data related to that particular part, such as a machine, sensor, or subsystem. This type of digital twinning provides information about how certain parts are working and performing. It helps you figure out when maintenance is needed, improves how tasks are done, and boosts overall effectiveness.

Let’s take the example of an electric motor. In this case, the digital twin processes datasets (current, voltage, temperature) to ensure optimal motor operation. If any readings are out of standards, the virtual model alerts the operator that maintenance is required. Such procedures detect problems in the early stages, which allows companies to avoid breakdowns and accidents.

#2. Asset Twin

This virtual copy consists of multiple sections that either model certain real-world elements of the object or use the data produced by those pieces to represent the entire item. An asset digital twin shows engineers the way different parts interact with each other and work as a whole. For instance, examining which component can operate better, how to cut down on failure and recovery times, and how to use resources more sparingly.

An excellent example of a component digital twin is the project Visartech worked on. The team helped the client create a 3D virtual representation to investigate a 3-axis scanner designed for weld inspection or line scanning.

#3. Process Twin

The term “process twin” stands for a digital representation of networked systems. This particular type of virtual twin tells if all these systems are synced to function as effectively as possible. It provides maximum insight into the processes and workflows within the enterprise. As a result, companies get a more in-depth and diverse analysis of products and services.

For instance, a VR-based business process solution our development team created for an automotive company. This twin is a digital representation of the company’s processes and how they interact in a networked system. Vizualized resource intensity of each process in real-time allows for data-driven decisions and optimization of the company’s overall operations.

#4. System Twin

This is a way of creating system copies that allows companies to replicate and analyze assets at a system-wide level. Bespoke virtual twin engineering of this type represents how different assets work together forming functional units. The digital twin system provides an overview of the company, allowing business owners to test different configurations to achieve maximum efficiency or identify new opportunities to increase profits.

Consider auto manufacturing as an illustration. In this case, a digital twin development company includes physical structure, production processes, equipment, resources, and other important elements into a virtual copy of a factory. For example, data on production lines, equipment placement, number of employees, work schedules, materials, inventory, and more. It simulates, analyzes, and optimizes various aspects of production without the need to change the actual system.

As explored in this section, the custom digital twin development process typically begins with smaller components and assets, gradually evolving into comprehensive virtual modeling of complex ecosystems. When considering the right choice of a virtual twin, it’s crucial for organizations to carefully assess their specific needs and objectives, taking into account factors such as scalability, accuracy, and cost-effectiveness. By doing so, enterprises can take full advantage of the predictive digital twin for enhanced decision-making.

Digital Twins vs Digital Thread: Understanding the Difference

Both digital twin and digital thread are the concepts of digital transformation drawing upon 3D technology. However, they have different functions and focus on different aspects of business process optimization.

As mentioned above, a digital twin is a virtual counterpart of a physical system or thing. While a digital thread is the digital record of an end-to-end product’s lifecycle. Other differences between these software solutions are:

- Scaling

Virtual twins have some scaling restrictions. In theory, engineers can connect it to other 3D copies to simulate a digital environment, but their primary use is in evaluating a specific production environment. In contrast, the scalability options for digital threads are endless. It’s possible to link them to any other systems and procedures within the organization, including digital copies.

- Data Centralization

Digital twins and digital threads collect complete sensor data and store it in a data center for easy access. However, unlike the virtual copies, digital threads provide teams with information from many sources, including digital twins. They also merge the data flow across departments and business processes, facilitating smooth collaboration.

- Usage

Custom digital twin development is commonly used for design optimization, predictive maintenance, and monitoring the performance of complex systems. A digital thread’s objective is to offer a unified picture of the product’s information, facilitating greater teamwork, quality assurance, and legal compliance.

Creating 3D digital copies is an excellent solution for businesses aiming to understand object behavior in real time and make important decisions quickly. Digital threads will make it easier for parties to work together and coordinate their efforts and provide data traceability.

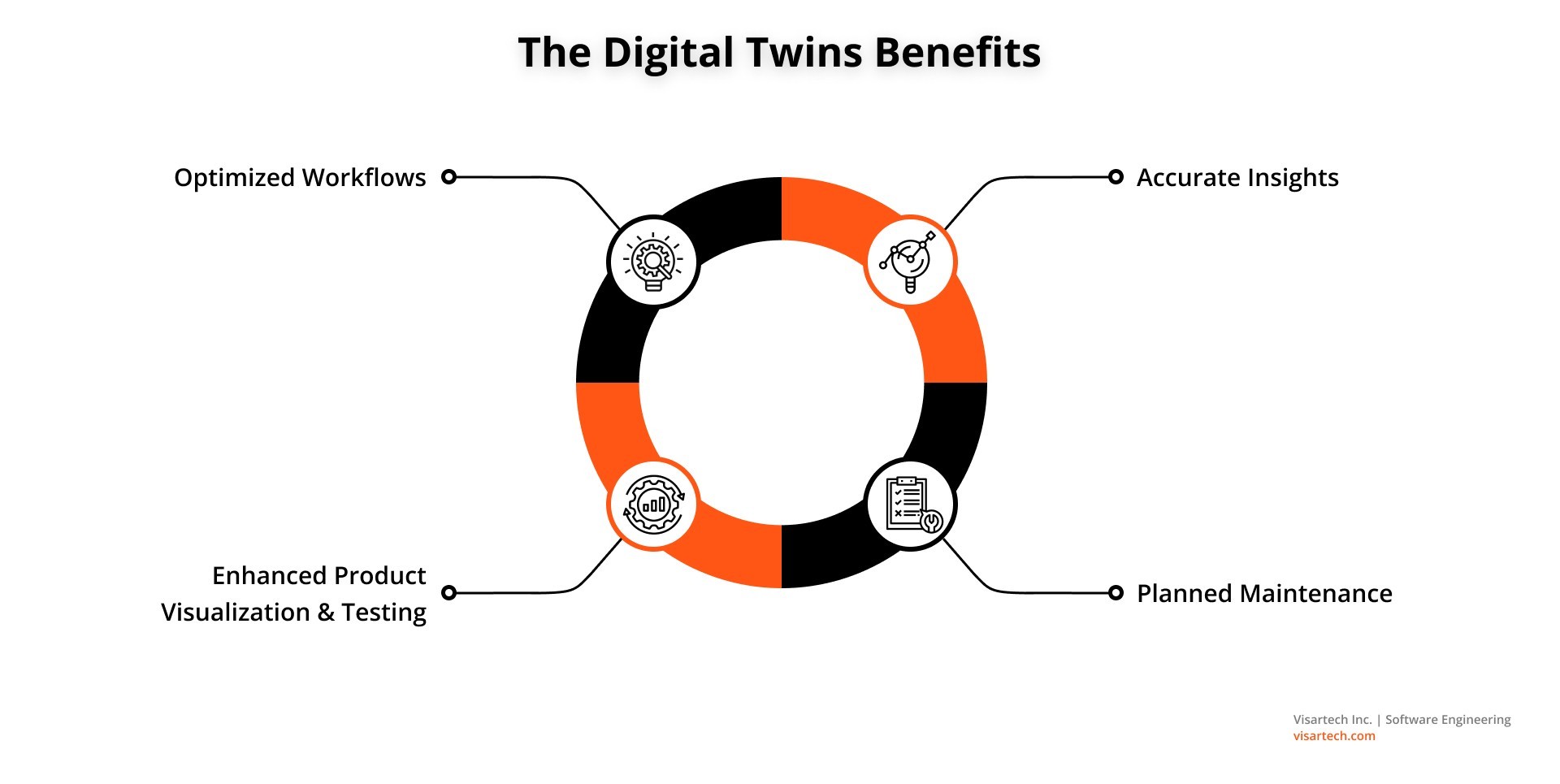

Advantages of Digital Twin Development for Businesses

Virtual twin is a solution that companies use to achieve a set of improvements within the business, rather than solving just one problem. This approach is motivated by four main benefits of digital twins:

Optimized Workflows

Digital twin development facilitates effective collaboration among geographically dispersed teams by offering a virtual representation of products, processes, or systems. By accessing shared information simultaneously, team members can engage in iterative problem-solving and knowledge sharing. Instant updates based on the shared data create a dynamic and efficient work environment.

Read also: How Workflow Management Software Can Power Up Business

Discover how to automate business processes and boost productivity

Accurate Insights

Enterprises that make thoughtful decisions quickly are becoming winners and building a digital twin assists them in completing this task. With 3D virtual modeling, you can simulate different scenarios and understand the consequences they will have. This is also a workable method for analyzing the existing product, as virtual twins show whether there are options for better design, size, functionality, and so on.

Enhanced Product Visualization & Testing

A digital twin of a product is an exact copy that companies can view on the screen or through AR/VR visualization. By carefully examining every intricate detail of the product prior to its physical production, businesses understand its strengths and weaknesses. This approach is also beneficial when testing different units’ components or parameter settings. Notably, this is especially convenient for organizations that create customized equipment for their customers.

Planned Maintenance

It’s quite challenging to track the state of all business resources and equipment. Since digital twinning analyzes data to track the performance of various assets in real-time, companies can anticipate potential failures or service needs before they become problems. This minimizes unplanned downtime by identifying and extending asset lifespan through systematic maintenance, preventing damage and wear.

The most exciting part is that you can apply digital twins in different business spheres gaining the above-described benefits at all levels of operations. Furthermore, the flexibility of virtual representations allows companies to adapt and scale their implementation based on specific needs and requirements, leading to comprehensive improvements.

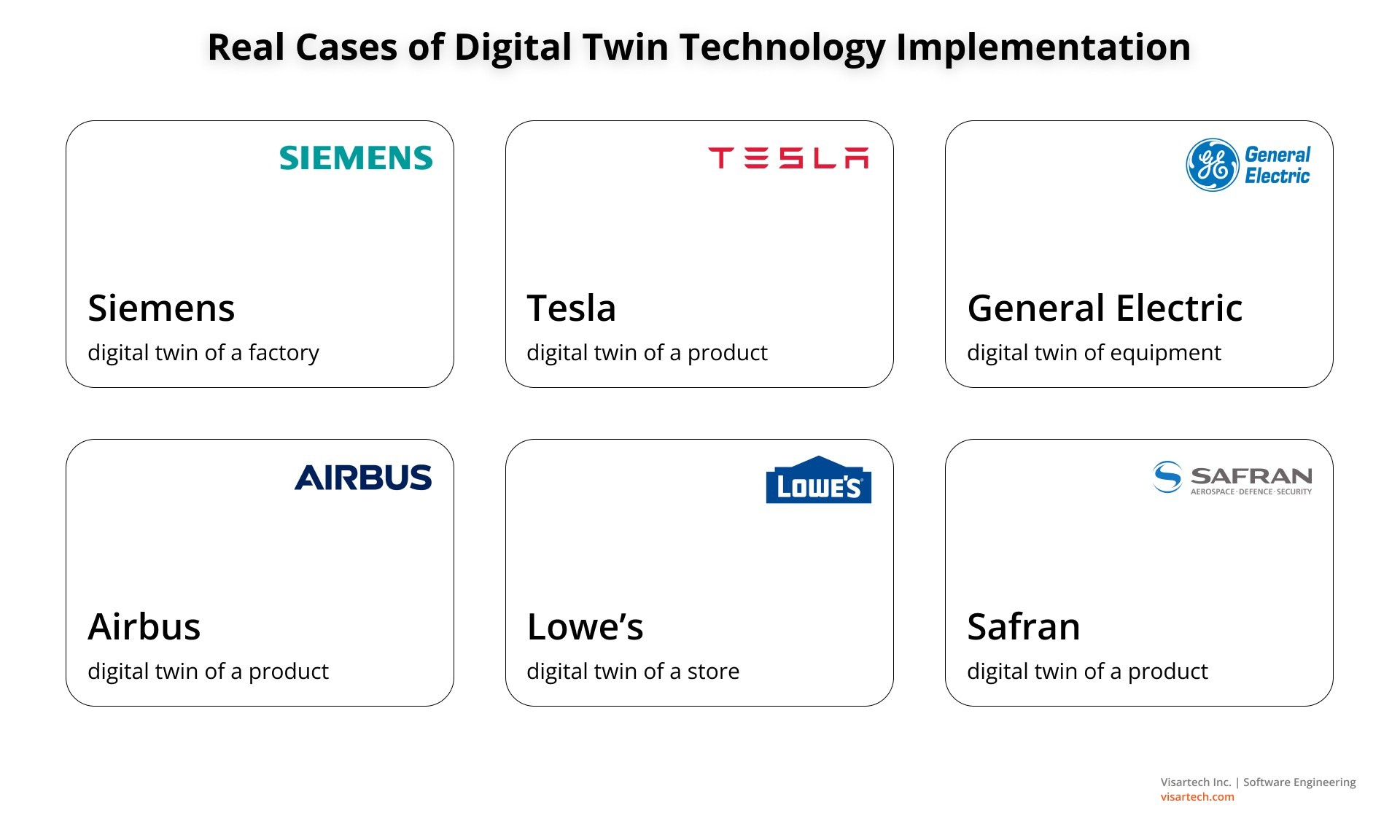

6 Companies Proving Successful Digital Twin Use Cases

Virtual twins can take many forms, but they are most valuable when used as digital twins of an organization. A complex digital twin model is capable of combining process and contextual data. It can provide insights into how your organization utilizes its business model, adapts to changes, and delivers value to customers.

With a true enterprise-grade digital twin, you can simulate the dynamic operation of your company’s whole system.

Digital twins have become the go-to tool for businesses looking to detect issues timely and boost productivity. Some of the largest companies in the world are already reaping the benefits of using virtual copies in various ways. Let’s zoom in on these digital twin examples below.

#1. Siemens

The tech giant has used custom digital twin development as a foundation for building a smart factory at a Chinese subsidiary. Utilizing the information flows from the running assembly lines, Siemens has developed scenarios for eliminating constraints in production and maximizing resource usage at the plant. This helped increase machine utilization by 40%.

#2. Tesla

Tesla is developing a custom digital twin for every vehicle before releasing it for sale. Sensors transmit data to a 3D model of the car, where analytical tools interpret them and determine whether the car is working as intended or needs maintenance. By taking this action, the company reduces the costs associated with maintaining vehicles covered by warranties.

Read also: Automotive Technology Trends Emerging in 2023

Explore tech advancements that foster automotive industry growth

#3. General Electric

GE showcased digital twin use cases in the energy sector in 2018. The company has developed a 3D virtual model of the rotary engines of the Haliade 150-6 wind turbine. With this software solution, employees monitor the internal current to see how hot the motors will run. The custom digital twin development helps the company to evaluate the efficiency of the machine and determine when it is best to rev up or down the engine speed.

#4. Airbus

Airbus employs a virtual twin system to continuously monitor and analyze the operational aspects of its aircraft in real time. The 3D model presents comprehensive data regarding various operational parameters, including fuel consumption and engine efficiency.

This reveals the need for changes in the design, operation, or maintenance of the aircraft. As a result, Airbus has succeeded in reducing fuel consumption and emissions, improving efficiency, and fostering sustainability within the aircraft industry.

Lowe’s

Lowe’s, an American retailer specializing in home goods, has pioneered the concept of “intelligent stores” — virtual replicas of physical shops. Here’s the mechanism behind these stores: the digital twin uses historical data to create AI avatars. They estimate walking distance for frequently bought together.

In essence, this helps employees to find the best locations for products to improve the customer and associate experience.

Safran

Industrial digital twin allows Safran to specify the expected performance of the braking system and its components according to the aircraft manufacturer’s requirements. By analyzing various scenarios and conditions virtually, the company ensures the system meets all operational needs and avoids incorrect component performance analysis.

As Jerome Fraval, Systems Modeling Lead Engineer at Safran pointed out:

“Today the use of model-based systems engineering is essential in our industry because incomplete knowledge of all the operational cases can lead to an incorrect analysis that originally aims at specifying the component performance.”

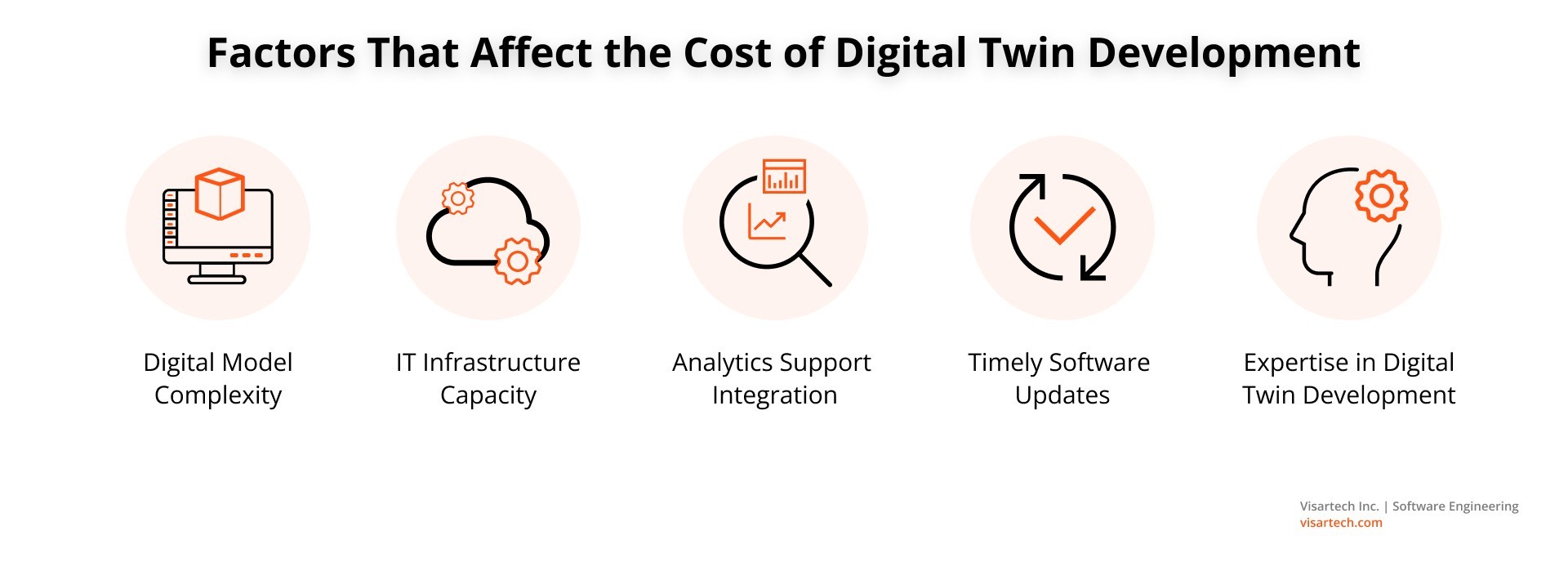

How Much Does It Cost to Create a Digital Twin Solution?

The cost of developing and implementing a virtual copy depends on various factors:

- digital twin’s features & complexities;

- business strategies;

- digital twin development tools;

- desired outcomes.

In some cases, a single 3D model may suffice, while others need multiple twins. Let’s see how much it will cost to develop the basic prototype of the digital twin asset.

First and foremost, the costs associated with developing a digital twin will rely heavily on:

- Digital Model Development

The digital copy may come in various sizes and simulate the object’s behavior and characteristics with different levels of accuracy. Accordingly, this will affect the development of the asset digital twin.

- Infrastructure Development

This includes investing in cloud computing resources or building a robust infrastructure to host and manage the digital twin. The cost will depend on the scale of the asset, the computational requirements, and the tech stack selected.

- Analytics Support

Digital twin architectures use different analytics support. It includes prescriptive analytics, optimization analytics, and predictive analytics. You may require additional investment due to the complexity of integrating the results from these data analyses with existing business systems and workflows.

Read more: Business App Development Cost in 2023

Check out the comprehensive guide on app development cost

- Timely Updates

To stay up-to-date, virtual representations require data validation, model recalibration, and software updates. The cost of ongoing maintenance will vary based on the complexity of the asset and the frequency of upgrades.

- Expertise in Digital Twin Development

The costs of 3D virtual copy development differ according to the expertise required, which relies on factors such as geographic location, skill level, and experience. Higher levels of specialized skills demand higher rates, increasing the overall budget for creating a digital twin.

Speaking of experts, the dedicated development team for creating a starting version of asset digital twin will consist of:

- Front End Software Engineer;

- Back End Software Engineer;

- System Architect;

- 3D Tech Artist;

- DevOps Engineer;

- QA Specialist;

- Project Manager;

- Business Analyst.

They work together to create the exact 3D copy of an asset, build a rotating module, include animation capabilities, integrate the virtual twin into the system, and test its characteristics. The estimated price range for a basic asset digital twin with these functionalities is between $79,000 and $132,000.

The Full Cost Estimation for Creating an Asset Digital Twin With Fundamental Features

Check the accurate pricing details, the dedicated development team structure, and the tech stack needed to bring your digital twin to life.

Final Thoughts

Digital twin development helps to understand complex systems and processes in a virtual environment. For businesses worldwide, it turns into making more informed decisions, predicting equipment malfunctions, and thereby avoiding risks of failure and associated costs.

The requirements for creating an effective digital twin are quite high with the need for skills such as accurate 3D model development and advanced analytics. Ultimately, partnering with a trusted digital solutions provider greatly enhances the journey toward creating a seamless and successful virtual representation, offering expertise and support every step of the way.